Table of Contents

- The Rise of ASCs: Challenges and Opportunities

- Shifting To Value-Based Care and Addressing Issues with Technology

- How QRS Addresses ASC Efficiency and Safety

Value-based care (VBC) is a growing trend throughout healthcare, including in ambulatory surgery centers (ASCs). VBC bases health care provider earnings on the results they get for their patients. Earnings are tied to factors like quality, health outcomes, and cost effectiveness. It is hoped that by shifting away from the traditional fee-for-service model will improve these factors.

VBC presents some unique challenges in the outpatient surgery market. Our chief commercial officer, Farzin Khaghani, recently discussed these issues on Becker’s Healthcare Ambulatory Surgery Centers podcast. He shared how Maxx Orthopedics is partnering with surgery centers to provide technical solutions.

The Rise of ASCs: Challenges and Opportunities

Outpatient surgery centers represent a rapidly growing segment of the healthcare delivery market. As Mr. Khaghani shared, even before the pandemic, 50% of patients were expected to shift from traditional hospital settings to ASCs within 5 or 10 years. Today, ASCs are almost already there. ASCs are expected to grow 22% by 2033.

Outpatient surgery centers represent a rapidly growing segment of the healthcare delivery market. As Mr. Khaghani shared, even before the pandemic, 50% of patients were expected to shift from traditional hospital settings to ASCs within 5 or 10 years. Today, ASCs are almost already there. ASCs are expected to grow 22% by 2033.

According to the American Joint Replacement Registry’s 2023 annual report on hip and knee arthroplasty procedural trends and patient outcomes, there are now 42,228 procedural cases reported by ASCs annually, an 84% increase from the year prior, according to the report sent to Becker’s on Nov. 3.

Patients are increasingly choosing ASCs for value, patient care, and outcomes. Now, ASCs and their industries must meet the demand and provide safe, efficient solutions.

It has long been established that ASCs provide clinical benefits. It improves patient outcomes and maximizes cost savings. The right patients are being funneled into outpatient care, leading to outstanding results.

ASCs are saving patients, Medicare, and third party payors money on surgical procedures. Medicare alone saves about $2.6 billion per year paying for ASC instead of hospital procedures.

The business side of increasing demand for outpatient surgery presents more challenges for outpatient centers, including efficiency. To remain profitable, ASCs must be efficient. Challenges include limited space, sterilization capacity, managing a lot of surgical trays, and patient throughput.

Surgical trays represent an important area of potential improvement for costs and efficiency. Studies have found that trays are often overcrowded with unnecessary instruments that increase costs. Optimizing and reconfiguring trays using mathematical programs can save money and reduce inefficiencies.

Shifting To Value-Based Care and Addressing Issues With Technology

Many ASCs are shifting to VBC to manage the challenges they face with growing patient numbers. VBC offers cost savings along with improved patient outcomes.

To achieve these two goals, ASCs are increasingly working with industry partners, like Maxx Orthopedics. Device manufacturers must now do more than just provide implants. They also deliver efficiency to help outpatient centers run profitably without compromising patient safety.

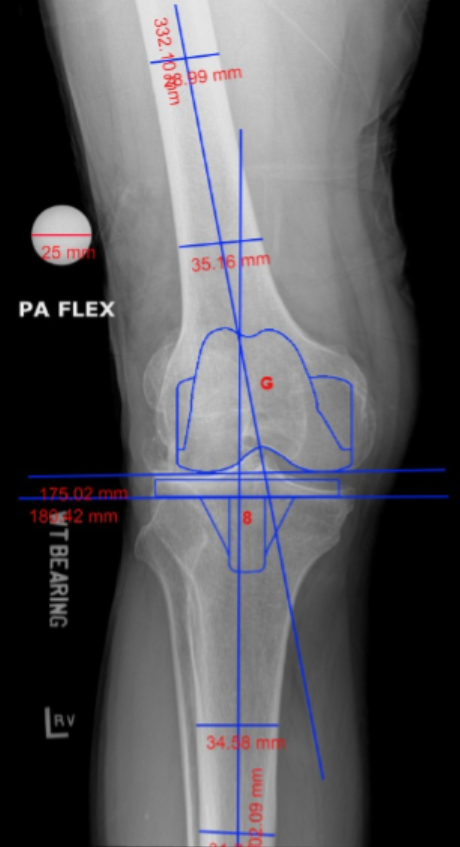

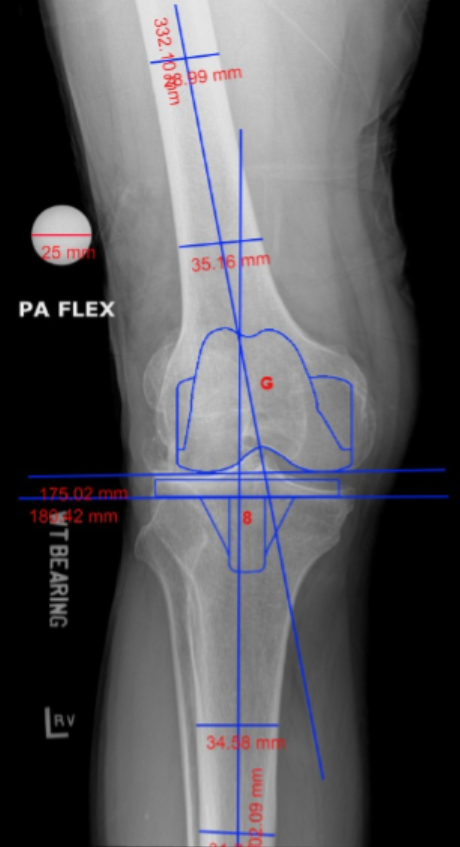

Partners like Maxx Orthopedics develop solutions using technology. They leverage software and imaging to deliver the best implants for individual patients. This makes the process of surgery more efficient and safer. New software programs find and manage inefficiencies in every part of the surgical and patient care delivery processes.

How QRS Addresses ASC Efficiency and Safety

Maxx Orthopedics introduced Quick Recovery Solutions in response to the need for greater efficiency in delivering patient care in outpatient settings. Maxx works with surgeons to provide them with surgical trays containing everything they need and nothing they don’t need.

Maxx Orthopedics introduced Quick Recovery Solutions in response to the need for greater efficiency in delivering patient care in outpatient settings. Maxx works with surgeons to provide them with surgical trays containing everything they need and nothing they don’t need.

For example, when providing total knee arthroplasty instruments and implants, QRS includes an implant selected specifically for the patient undergoing the procedure. Using sizing software, Maxx creates the right implant for that patient and includes only the instruments the surgeon needs in the tray.

This solution removes inefficiencies in the pre-operative process and during surgery. ASCs receive only what they need, which reduces storage complications, total sterilization trays for surgical instruments, and other equipment.

QRS has allowed surgery centers to reduce the number of instrument trays stored and used per procedure. Where an ASC with five procedures per day might have juggled 15 to 20 trays, they now only need five. This makes every part of the process simpler, including setting up and breaking down the OR.

These improvements in efficiencies help ASCs increase patient throughput, but patients also benefit. Faster surgeries are safer and correlate directly with fewer infections. Surgeries are always safer when the surgeon has only what they need to perform the procedure and less clutter.

Maxx Orthopedics continues to provide high-quality implants sized for individual patients. We are also dedicated to partnering with ASCs in other ways to improve efficiency, costs, and patient outcomes. This includes the further development of the QRS platform. Learn more about our Quick Recovery Solutions and how they benefit surgery centers, surgeons, and patients.

Outpatient surgery centers represent a rapidly growing segment of the healthcare delivery market. As Mr. Khaghani shared, even before the pandemic, 50% of patients were expected to shift from traditional hospital settings to ASCs within 5 or 10 years. Today, ASCs are almost already there.

Outpatient surgery centers represent a rapidly growing segment of the healthcare delivery market. As Mr. Khaghani shared, even before the pandemic, 50% of patients were expected to shift from traditional hospital settings to ASCs within 5 or 10 years. Today, ASCs are almost already there.

Maxx Orthopedics introduced

Maxx Orthopedics introduced